About Preconditioning Cells |

|

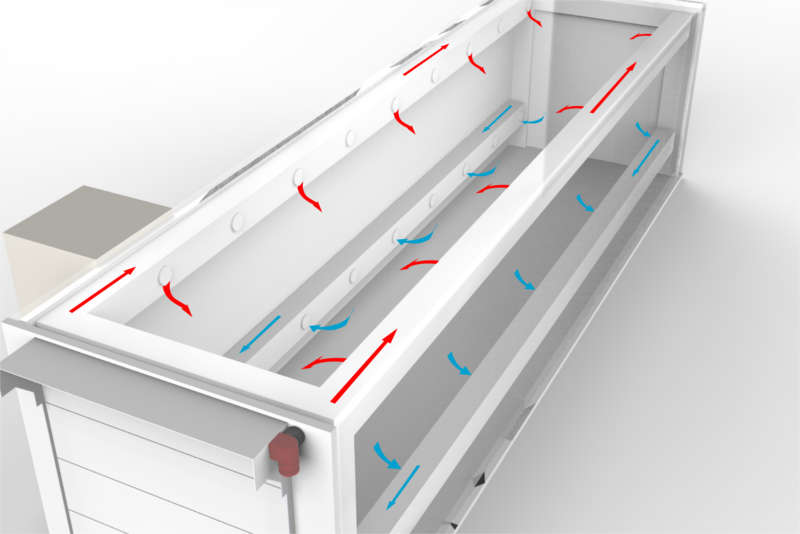

| Airflow is key |

Typically preconditioning cells are fabricated from insulated panels forming a cell with internal dimensions identical or close to the sterilisation chamber dimensions. From the outside most cells look similar but often vary greatly in performance. This can be down to a number of factors that aren't obvious from the outside. Without giving too much away our cells have been developed of two decades create a tight boundary flow across the all surfaces within the load with a close temperature and humidity tolerance. |

| High Quality Insulation |

Combined with high quality insulation our cells offer optimum preconditioning performance Tight control of humidity stops condense within the cell and together with the robust cell structure this ensures a long life. |

| Flow v's energy the optimum balance |

Having had the opportunity in the past to test various air change options we have optimized the cell to ensure the highest return for energy input. |

|

Would Vacuum Preconditioning Work? |

Yes the same shallow vacuum technology would most certainly speed up the product load reaching temperature and humidity. For the time being however most users do not have a time problem in preconditioning. If you have a different experience with preconditioning being a bottleneck we would be very interested in applying our vacuum technology to your application. |

| Compliance |

The preconditioning cell process has been assessed to identify any EU Directives, regulations and standards. The preconditioning cell was then designed, assessed and tested against the identified directives

- EN ISO 12100: Safety of Machinery - General Principles for Design - Risk Assessment and Risk Reduction

- EN ISO 13849-1: Safety of Machinery - Safety-related Parts of Control Systems - Part 1: General Principles for Design

- EN 60204-1: Safety Of Machinery - Electrical Equipment Of Machines - Part 1: General Requirements

- EN 61000-3- 2: Electromagnetic Compatibility (emc) - Part 3-2: Limits - Limits for Harmonic Current Emissions (equipment Input Current <= 16 a per Phase

- EN 61000-6-1: Electromagnetic Compatibility (emc) - Part 6-1: Generic Standards - Immunity for Residential, Commercial and Light-industrial Environments

- ATEX Directives: 2014/34/EU Equipment intended for use in Potentially Explosive Atmospheres (Zone 2). This refers to specific PC door equipment only, located in Zone 2 atmosphere.

|

Contact us |

For more information on these or any of our services and products, our team will be happy to answer your questions

Contact us

|